Introduction

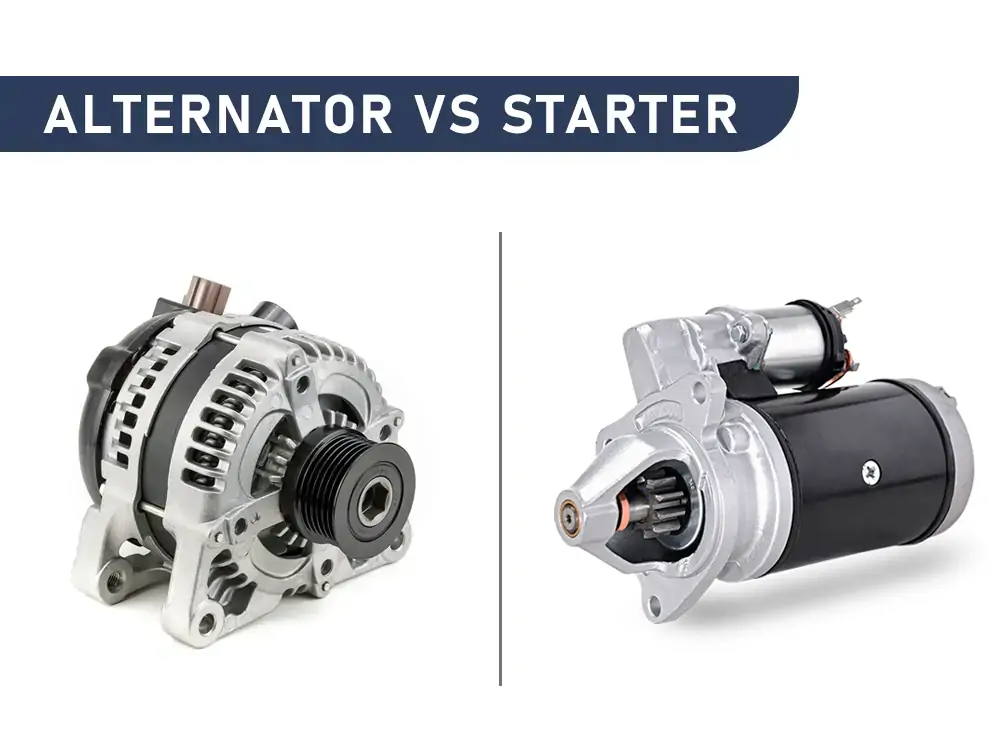

The starter motor, alternator, and battery compose the vehicle’s “electrical trifecta.”

These under-the-hood components are critical devices that keep the car running. The starter and alternator are often compared. Still, many are not fully familiar with which one is which, and they fail to diagnose problems involving either component.

This article explores the differences and complementary works of the starter and alternator. Read on to understand their distinct functions and performance.

What is a Starter?

An internal combustion engine needs an air-to-fuel mixture to start ignition. But such a necessity isn’t readily available inside the engine. The pistons must first move to ignite the right amount of air and fuel.

So, what engages the pistons? This is where the starter motor plays its vital role.

Definition and Function

The starter functions precisely as it sounds. It’s a device that initiates the engine to run.

Once you turn the ignition key or press the start button, an electrical signal is sent to the starter motor. When activated, the starter extends its pinion gear to attach to the engine’s flywheel, which is connected to the crankshaft.

The starter draws significant power from the battery to turn the flywheel. This rotation then turns the crankshaft and engages the piston movement. Such movement draws an air and fuel mixture, which the spark plugs ignite. Once the ignition is successful, the pinion gear retracts. At this stage, the starter’s function is complete.

Components

While the starter motor appears trivial in size, it has several components inside. These parts work in unison to keep the starter working. But they, too, are susceptible to breaking.

- Solenoid

- Pinion gear

- Driveshaft

- Armature

- Brushes

- Commutator

- Field coils

- Drive gear

- Electrical connections

- Bearings

- Brush holder

- Starter motor housing

Bad Starter symptoms

You must check your starter motor when it shows signs of failure. Here are the most common symptoms that a bad starter exhibits. View more complete starter motor failure symptoms.

- Engine that doesn’t crank or cranks slowly

An engine that cranks slower than it should is a potential sign of a struggling starter. This can mean the starter isn’t getting enough power to turn the engine over. When the engine doesn’t crank, the starter fails, or some loose connections are the culprits.

- Grinding noise

A grinding or squealing noise isn’t part of a healthy starter. This could point to a compromised pinion gear. You’ll hear strange noises when the pinion gear does not correctly mesh with the flywheel.

- Headlights turn on, but the engine doesn’t start

Pointing to a starter motor when your headlights or radio are working is reasonable, but your engine won’t start. The functioning electrical components mean your battery is okay. So, the problem can be in other components, probably the starter.

- No sound

Hearing no sound is equally problematic as hearing a grinding noise. No sound indicates zero activity in the starter motor. This most likely means that the pinion gear isn’t engaging. There could be several reasons for this. One is a connection problem that’s causing power delivery loss. Without power, the solenoid can’t engage the pinion gear.

But if the connection problem isn’t the issue, the trouble can be with the pinion gear itself. Or the solenoid may be malfunctioning, preventing the pinion gear from meshing with the flywheel. Click here to see how to replace the starter motor.

What is an Alternator?

A car has many electrical components that consume power. The starter alone draws significant power to start the ignition. Hence, there should be a device that will recharge the battery to avoid power loss. This function rests on the alternator.

Definition and Function

The alternator is a small alternating current (AC) generator found in vehicles. It’s responsible for converting mechanical energy into AC power.

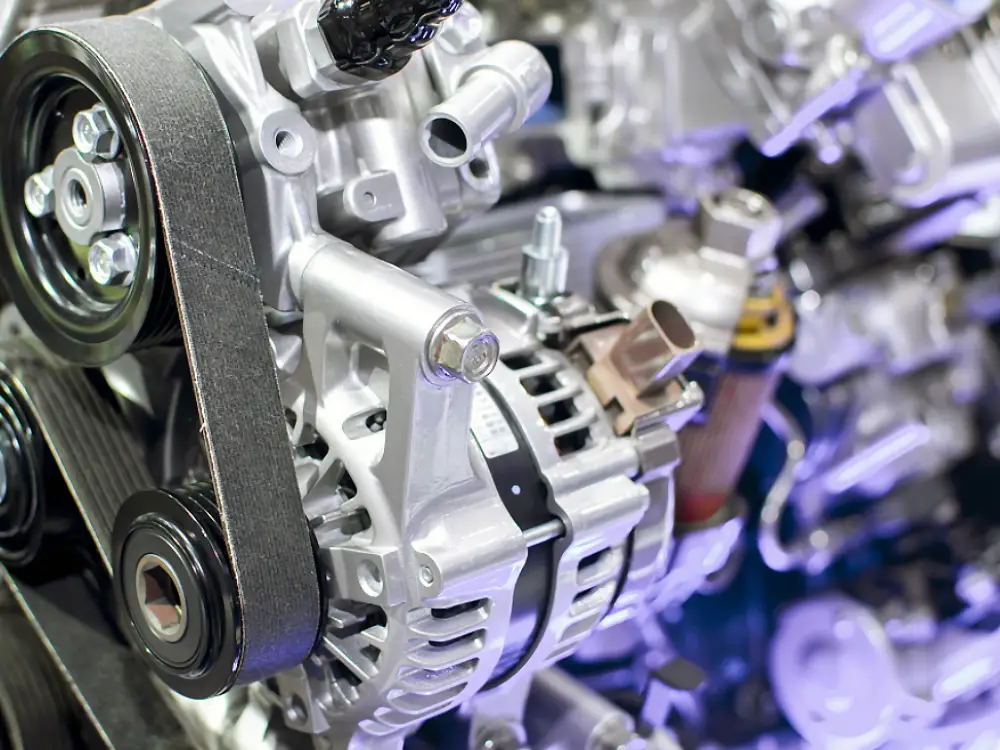

When the engine runs, it spins a serpentine belt connected to the alternator’s pulley. This action rotates the rotor inside the stator, which induces alternating current.

For the AC to power the devices and charge the battery, it must convert to DC. So, the AC runs through the rectifier for DC conversion. This process allows the alternator to recharge the battery and prevent the power from depleting.

Components

Like a starter motor, the alternator is also composed of different parts. These parts are responsible for generating electricity and recharging the battery.

- Stator

- Rotor

- Brushes

- Voltage regulator

- Rectifier

- Pulley

- Slip rings

- Cooling fan

- Terminals

- Bearings

- Housing

Bad Alternator Symptoms

The signs of a bad alternator can be easy to spot. When the alternator fails, it affects the entire power system. Often, problems with your battery can be related to a compromised alternator. Here are the most common signs of a failing alternator.

- Dead battery

A dead battery is a vital sign of a bad alternator, especially if your battery is supposed to be new. A failing alternator will not charge the battery properly, causing it to die eventually.

- Battery warning light

When the battery warning light illuminates your dashboard, it could be a battery or charging system problem. This issue may point to the alternator not charging the battery as it should.

- Low voltage reading

A low voltage reading can signal poor battery charging. Your resting voltage should not read lower than 12.2 Volts. It can mean your battery needs replacement but can also be due to potential alternator trouble.

- Dim or flickering headlights

When your headlights flicker or turn dim, there isn’t enough power. This issue points to inconsistent voltage and power, likely caused by a malfunctioning alternator. Especially when driving, a flickering light can be a good indicator that the alternator isn’t providing enough charge.

Differences Between Starter and Alternator

The starter and alternator are complementary components. However, while they work together, they remain distinct.

Functionality

The starter initiates the ignition process. It engages the cranking of the engine and disengages once the engine is running independently. The starter’s duty ends once the engine combustion is successful.

The alternator starts to work when the car starts running. It will remain functioning until the car turns off. Its major role is to turn mechanical energy into electricity to power devices and charge the battery.

Operation Timing

The starter’s operation timing commences when you initiate the ignition. Once the electrical signal reaches the starter, the solenoid connects the battery to the motor. The solenoid then engages the pinion gear to mesh perfectly with the flywheel. When the engine is running, the pinion gear stops spinning and retracts.

In contrast, the alternator’s operation timing is more systemic. It includes the mechanical timing of the engine and the alternator’s rotation. The correct belt tension is needed to guarantee efficient alternator performance.

Additionally, the alternator needs regular voltage flow despite the changing engine speed. It must also synchronize with the car’s electrical demands. Only when the engine switches off does the alternator rest.

Power Supply

For the starter to work, it will need significant power from the battery. A higher power output will be required to rotate the engine crankshaft. So when you have a faulty battery, you’ll also have a defective engine start. The car battery must reach optimal charge for the starter to complete the ignition process.

In contrast, the power supply needs the alternator to recharge. Starting the engine draws significant power, so it needs to be replenished. The alternator functions because of the mechanical energy from the engine.

Even with a drained battery, the alternator will still function as long as the engine runs. In return, the engine rotation powers the alternator, which powers the devices and the battery.

How They Work Together

The starter motor’s role is to get the engine running. The alternator maintains the electrical system once the engine is operational. Although they may perform distinct tasks, they must work together to keep the car uninterrupted.

If a starter motor fails, the engine won’t start. The alternator can’t run if the engine isn’t running, too. In essence, the alternator can only function if the starter functions. Conversely, a faulty alternator can drain the battery. This can affect the performance of the starter as it draws power from the battery.

Knowing this relationship should compel any car owner to give equal attention to both components.

Conclusion

When compared, the starter motor and alternator clearly serve distinct but complementary roles in a vehicle’s operation. They are equally essential components making up the car’s electrical trifecta.

Their roles underscore the importance of both components in ensuring reliable engine performance. Regular maintenance is a must to keep them in top shape. Once you see signs of either component going bad, you must act immediately to avoid further damage.

Remember, a starter will not function as it should if the alternator fails. In return, the alternator cannot function if the starter doesn’t function in the first place.